Often when a TXM consultant talks with a new client, the important concern is sustaining business improvements after the initial excitement of implementation has died down. We have found many times that well implemented tee-cards, done with the shop floor teams, are an integral part of sustaining our housekeeping and preventative maintenance efforts.

What are Tee cards?

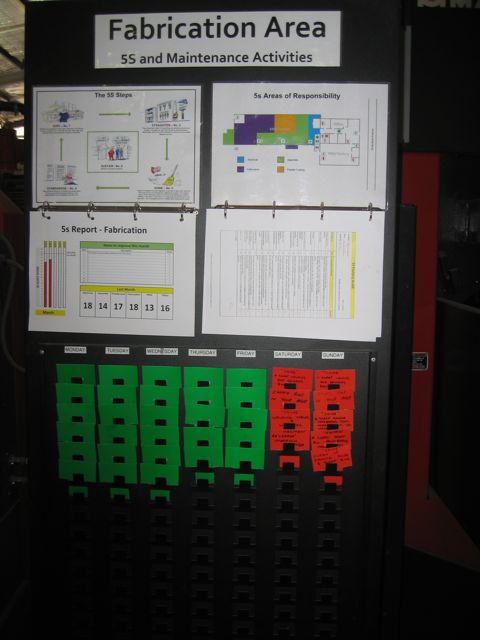

Tee cards are cards cut into a “tee” shape to fit into a louvered panel. They are red on one side and green on the other. This allows them to be used as simple, visual reminders of the tasks that need to be completed each day.

Tee cards are cards cut into a “tee” shape to fit into a louvered panel. They are red on one side and green on the other. This allows them to be used as simple, visual reminders of the tasks that need to be completed each day.

After the kick-off of 5S, when the Sort, Set in order and Shine phases are complete, we need to consider which housekeeping activities are needed to standardise and sustain our improvements. The challenge with housekeeping, as we know from our own homes, is that we start the week with good intentions (I will keep my bench clean) but as we get busy, work priorities take over and housekeeping efforts slide.

At other times, each housekeeping task may seem too small to worry about every day, but if we leave all of these tasks to the end of the week, then there is a lot of work to do to return the area to our standard of cleanliness ad it become s a much bigger task. This is where the tee card are really effective.

How Best to Implement Tee Cards?

The best way to implement tee cards and ensure buy-in from our teams is to involve them. Once the first Sort, set in order and shine is complete, list the activities that are needed to sustain the area. This may include items such as:

- Empty rubbish bins x2

- Check first aid cabinet

- Complete forklift checklist, every day

- Check oil level in machine

- Refill paper in copier and wipe glass

- Sweep floor

- Brush off benches

Also discuss how often they are needed to be done. Emptying the bin once a week may not be enough, so let’s try to empty it twice a week. Sweeping may only be needed once a week, unless something unusual happens.

Now we have a list of activities, discuss how best to spread them out across the week; bins Tuesday and Friday, sweeping Wednesday, oil level checks Thursday, for example. Write the activities out on each tee card (on both sides) and place them on their set days. As a group, decide if you will set aside 10 minutes each day to complete the 5S activities or leave it up to the people in the area to complete the tasks during the day.

Sustaining 5S Actions with Tee Cards

Add an agenda item to the morning, stand up meetings to review the progress of the 5S tasks. If they are not getting done, consider why; are the tasks too big to get done in the allocated time? Does each team member understand what is needed to complete the task? Is everyone helping out?

Review the tasks after 3 weeks and look at the which days the tasks are begin done on and the size of each task; do they need to be combined (brush benches and sweep) or broken down into smaller tasks?

Tee cards are a simple way to sustain housekeeping across factories and are easily integrated into your Lean Journey.